Expert: 22+ Years of Experience

Seamless Clothing Manufacturer

- 100% Inspected Goods Delivered

- 3 Production Tracking Reports Provided

- Lower MOQ from a Large Standardised Factory

2 Easy Solutions

To Boost Your Seamless Clothing Business

Which scheme do you prefer? Our customized seamless clothing manufacturing solution has been designed to meet client needs while being both money-saving and cost-effective—kindly compare our SUPER MOQ and low MOQs with other factories!

#1. Customise New Designs

Discover a cost-effective, hassle-free, high-quality solution for customised seamless clothing manufacturing, with meticulous attention to detail in every step of the customisation process.

Custom designs can be tailored to suit different body types or individual preferences.

SUBMIT YOUR DESIGN

OR

#2. Your Logo, Our Stock Designs

Print your logo on our over 200 existing seamless activewear designs. Small orders are welcome, with a MOQ of just 1 piece.

REQUEST FOR CATALOGS

Custom Seamless Clothing Products Range

Customize your own seamless knitting design at the lowest MOQin the industry! Seamless clothing is crafted for comfort and designed to fit seamlessly into your everyday life, making it ideal for both active and casual routines. Tailor-made seamless clothing options are also available, allowing customization to specific measurements for a superior fit and comfort. The fabrics used are breathable, enhancing comfort for both active and daily wear.

Seamless Bra

Seamless T Shirts

Seamless Leggings

Tops & Shorts Sets

Compression Clothing

Seamless Shapewear

Seamless Underwear

Seamless Activewear

Submit your needs

Who are Seamless Clothing Manufacturers?

Seamless clothing manufacturers are factories specialising in the production of seamless apparel, using seamless circular knitting machines. China, in particular, is well-known for its extensive garment manufacturing industry and advanced production capabilities. These manufacturers are primarily located in China, Turkey, Italy, and other countries.

What is Seamless Clothing?

Seamless clothing is a one-step garment produced using a specialised Seamless Circular Knitting Machine.

Seamless manufacturing techniques allow for the efficient production of high-quality seamless apparel, utilising advanced technology.

The principle of seamless clothing production involves creating a three-dimensional curved surface with a fixed tube diameter and a consistent number of needles, along with variations in structure and raw materials. This process uses an innovative method—seamless knitting—which enhances the durability, fit, and comfort of activewear, representing a significant advancement in the industry.

Unlike garments made from cutting and sewing traditional knitted or woven fabrics, the torso sections of seamless appareltypically do not involve cutting or sewing limbs, or involve minimal cutting and sewing.

From yarn to ready-made apparel, the production of seamless clothing shapes the neck, waist, buttocks, and other areas without seams, combining comfort, practicality, and style. Seamless clothing also helps manage sweat by providing breathability and moisture-wicking properties, keeping the wearer dry during physical activity.

A powerful seamless activewear manufacturer supporting behind:

SANTONI top-level seamless knitting machines

0

+

Square meters of plant area

0

+

Employees with vocational skills training

0

+

New or mature brands cooperated, including wholesalers, retailers, shopkeepers, and even manufacturers

0

+

Why Choose Us

What You Get with YOU SEAMLESS:

Take a Steady Step for Your Seamless Knitted Garment & Activewear Business with YOU Seamless:

Clients are fully supported throughout every stage of their seamless clothing project, from concept to delivery.

100% Quality Inspection

Ensure that every apparel that arrives at the client’s hands is a top-class product that has passed the quality inspection.

3 Tracking Reports of Production

Make the delivery time & manufacturing progress under your control. Three tracking reports sent directly to your mailbox during the production process.

BSCI & SCOPE Certificated

The process of any international certification involves an inspection and promotion of our factory, and we are fully capable of passing most of them.

Maybe the Lowest MOQ

Starts from 100-200 pcs/color/size. All we want is to support you to develop faster!

365 Days Support

Providing efficient service and first-class products is the most enjoyable thing for us. You can find our team available at any time, even during holidays!

22 Yrs Top-notch Technology

We have cooperated with many large brands worldwide, familiar with yarn materials, fabrics, and production skills.

Seamless Clothing Production Flow

How to make seamless clothing? Unlike ordinary clothing, seamless knitted clothing is not simply about cutting and sewing fabrics. Our company specializes in producing high-quality seamless clothing using advanced manufacturing techniques to ensure efficiency and quality. These methods result in durable seamless clothing that can withstand frequent use and washing without losing its shape or performance. The mass production of seamless clothing involves drawing, weaving, dyeing, cutting, sewing, ironing, and packaging.

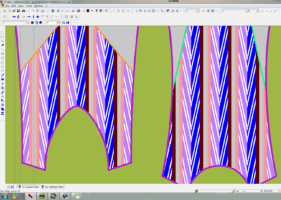

Program Making on Computer

Program Making on Computer

Knitting on Seamless Circular Machines

Knitting on Seamless Circular Machines

Dyeing

Dyeing

Cutting & Sewing

Cutting & Sewing

Final Cheking & Packaging

Final Cheking & Packaging

get free quote

What Kind of Seamless Activewear Manufacturer

are You Going to Cooperate With?

YOU SEAMLESS has a mature & standardized Production & Customer Service System to satisfy your OEM, ODM demands.

BSCI CERTIFICATION

SCOPE CERTIFICATE

ISO 9001 CERTIFICATED

ISO 9001 CERTIFICATED

Submit your needs

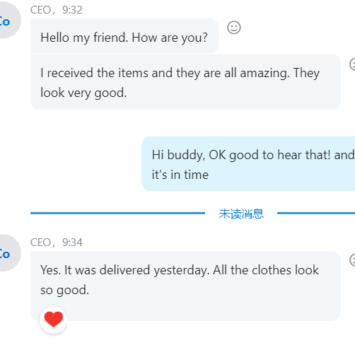

What They Say About Working With Us:

“We want you to revise the goods quality of the other suppliers in China. We trust your quality mark.”

“And we want everything to be as good as your production.”

“I received the items and they are all amazing. They look very good.”

“All the clothes look so good!”

Submit your needs

Seamless Clothing Factory’s Knitting/ Weaving Workshop

Seamless circular machine

110 Most Advanced Seamless Knitting Machines

To help in supplying our clients with top-quality seamless clothing, YOU SEAMLESS purchases top-notch branded seamless circular knitting machines like SANTONI to make even complicated designs.

YOU SEAMLESS has more than 110 of the best high-capacity devices for effective and constant production.

In order to ensure the timely and stable delivery of each client’s order, the weaving workshop adopts the working system of 24 hours, two shifts, and three operation.

The weaving workshop occupies more than 3,000 square meters on the ground, and sufficient production capacity ensures the infinite possibility of output.

Large-scale Factory, But Smaller Minimum Order Quantity

YOU SEAMLESS has a strong after-sales and technical team dedicated to providing premium quality products and services. Check out our updated brochure with a massive collection of wholesale seamless clothing available at affordable bulk rates and exciting deals!

We focus on creating custom seamless activewear for clients in Australia, New Zealand, United Kingdom, Europe, Canada, UAE, Saudi Arabia, and The USA. Over the years, we’ve become one of the leading seamless clothing manufacturers worldwide, offering designs that combine style and functionality.

As a trusted name among global brands, YOU SEAMLESS offers an impressive range of seamless activewear, including yoga apparel, sustainable activewear, and workout leggings. Our product range also features seamless sleepwear and sports bras, designed for comfort and performance. All our products are crafted with cutting-edge technology and premium quality to meet modern retail demands.

Most factories require a minimum order of 500-1000 pieces per design, but YOU SEAMLESS can support lower MOQs like 100- 500 pieces per design according to the complication of the designs. Contact our sales team to explore flexible options tailored to your needs!

Activewear Blog

Rock Crop Tops with Belly Fat: Easy Tips to Feel Stylish & Confident 2025

•

June 4, 2025

Are you hesitant to try crop tops because of belly fat? Don’t worry! Fashion should never be defined by body standards—it’s all …

Introduction to Regenerated Fiber Fabrics and Synthetic Fiber Fabrics

•

November 21, 2023

Regenerated fiber fabrics Regenerated fiber fabrics refer to fabrics made from various recycled fiber materials mainly composed of viscose fibers. There are …

•

November 7, 2023

Clean tips——Guide to stain removal Stains on clothing are an inevitable occurrence, and scientific methods can be used to remove the stains. …

•

October 25, 2023

The surface or gaps of clothing may be contaminated with foreign dirt or secretions from human skin. External pollutants include sandstorms, dust, …

What material or fabrics does seamless clothing factory

use to make seamless wear?

The fabric of seamless clothing is typically made from two or more types of yarns interwoven through seamless weaving. Many sustainable activewear brands now utilize organic materials, offering eco-friendly and environmentally conscious options. Here, we introduce five commonly used yarn materials, but they are definitely not limited to these five.

1, Cotton.

The permeability, comfort and environmental protection of cotton are irreplaceable by other materials, so we will add a certain proportion of cotton to many products. But now the industry is very developed. Often, there is no cotton in our seamless thermal underwear, but nylon, spandex, polyester and other blended fibers are used.

Cotton is a highly valued natural fiber in the world of seamless clothing, especially for seamless activewear and sportswear. Its exceptional breathability and softness make it a top choice for garments that need to perform under pressure, such as during intense workouts or daily active wear. Seamless cotton apparel allows for unrestricted movement, ensuring the body stays comfortable and cool even during the most demanding activities.

2, Nylon.

Nylon is a synthetic fiber renowned for its strength, flexibility, and resilience, making it a staple in seamless clothing production. Particularly favored for seamless sportswear, gym wear, and outer layer garments, nylon delivers a smooth, stylish finish that stands up to the demands of active lifestyles. Its superior durability and resistance to abrasion ensure that seamless activewear made from nylon maintains its shape and performance, even after repeated intense workouts.

Seamless activewear manufacturers rely on nylon blends to create garments that are not only cost effective but also high-performing and visually appealing. The smooth texture of nylon seamless clothing enhances comfort and allows for a full range of motion, making it ideal for both performance-driven sportswear and fashionable gym wear. For brands seeking to create stylish, functional, and long-lasting seamless apparel, nylon is an essential material that supports innovation and quality in every garment.

3, Polyester.

Polyester is the most widely used synthetic fiber in the world, surpassing acrylic fiber. Many of our commonly used common polyester only write abbreviated PET or PL.

Polyester is usually blended with other fibers, and a certain percentage of polyester fibers written on many garments are actually polyester. Because the amount of polyester fabric is relatively large, they don’t want ordinary people to think this is a low-grade thing. Sometimes customers also specify high-grade polyester. The high-grade polyester commonly used in our company is a brand of DuPont, called Coolmax.

Polyester is a versatile and high-performance synthetic fiber widely used in seamless clothing, from seamless activewear and sportswear to accessories. Known for its excellent moisture-wicking abilities, breathability, and quick-drying properties, polyester is the go-to choice for garments that need to keep up with an active lifestyle. Seamless polyester apparel ensures a comfortable fit, helps regulate body temperature, and supports optimal performance during any activity.

Seamless activewear manufacturers frequently use polyester blends to produce high-quality seamless apparel that meets the evolving demands of the market. Polyester’s advanced properties, combined with its eco friendly potential, make it a strong candidate for sustainable activewear production. Whether you’re developing seamless clothing for sports, fitness, or everyday wear, polyester offers the durability, comfort, and style that today’s consumers expect from premium seamless garments.

4, Spandex.

This is a polyurethane fiber Elastane fiber. The names of commodities are Lycra (Lycra, USA, UK, The Netherlands, Canada, Brazil), Neolon (Neolon, Japan), Rastan (Dorlastan, Germany), etc.

Lycra is commonly used in our company. Lycra, spandex yarn, polyester spandex, is a brand of Dupont company. Lycra fiber is a magical material. LYCRA can be freely elongated by 4 to 7 times and quickly returns to its original length after the external force is released. Some of our self-cultivation series include Lycra’s ingredients. The high elastic fiber mentioned in our domestic sales promotion refers to this kind of material.

5, Viscose fiber.

Such as matte silk, viscose, rayon, rayon, artificial wool, etc. Among them, the most famous one is Modal fiber, which is the cellulose regenerated fiber of high wet modulus viscose fiber developed by Lenzing Company of Austria. The raw material of this fiber is European beech, which is first made into wood pulp and then processed into fiber by a special spinning process.

6, Polypropylene fiber.

Polypropylene PP is the Chinese trade name for isotactic polypropylene fiber, a synthetic fiber made from propylene, a by-product of petroleum refining, which is also called polypropylene fiber.

Polypropylene has the following characteristics:

- The vertical plane is straight and smooth;

- The density is light, only 0.91g/cm3;

- High strength, excellent elasticity and good wear resistance;

- Wet strength is basically equal to dry strength, which is an ideal material for making fishing nets and cables;

- Moisture absorption and perspiration are obvious;

- Poor dyeing property;

- Corrosion resistance, but poor light resistance, poor thermal stability, easy aging, not resistant to ironing;

- High strength, second only to nylon, but the price is much lower than it. The fabric made of polypropylene fiber has stable size and good wear resistance. Therefore, polypropylene fiber is often used to weave carpets.

Quality and Reliability

At our seamless clothing manufacturer, quality and reliability are at the core of everything we do. Utilizing advanced seamless knitting machines and cutting-edge technology, we ensure that every piece of seamless apparel meets the highest standards for comfort, durability, and style.

Our seamless garments—including seamless activewear, seamless sportswear, and yoga wear—are crafted from premium fabrics and materials, carefully selected to deliver superior performance and feel. Our experienced team of designers and technicians collaborates closely throughout the production process, tailoring each garment to the specific requirements of our clients. With a steadfast commitment to customer satisfaction, we guarantee that our seamless clothing will not only meet but exceed your expectations, providing you with products you can trust for your brand.

Brief Introduction of

Seamless Clothing Knitting Process

Seamless clothing is basically worn close to the body and directly touch the skin, so the feeling of wearing is particularly important. Nylon & spandex, nylon & polyester & spandex, polyester & elastane, nylon & cotton (or Modal) & elastane, etc. all have good moisture absorption and antistatic sex after special dyeing processes, and their protein composition is similar to human skin, so it is soft and comfortable.

Although the cellulose fiber such as cotton hemp also is natural fiber, hygroscopic performance is right, regard seamless knitwear as comfortable also, but their softness and tactility are far inferior to super high quality seamless activewear.

A brief introduction of seamless garment weaving technology.

1, Weaving/ knitting equipment and parameters

-

The equipment

The sm8-TOP2 seamless knitting circular machine produced by SANTONI, Italy, is widely used by seamless activewear manufacturers in China at present. It is a single-sided once-forming computerized knitting jacquard machine with eight paths of yarn, and each path has two independent jacquard point (i.e., needle picker). Each path can carry out 3 levels of weaving at the same time (i.e., at the same time select needles for forming loops, collecting loops and lines).

-

Parameters

Electronic seamless apparel circular knitting machine with barrel diameter of 30-40cm(12-16 inches); The speed of 110 r/min; Needle selector for each 2; The feeding path is 8. Knitting circular machine capacity is 2.2KW, suction motor power is 3.9KW; The yarn guide is 8 / channel (in practical application can be less than 8).

2, Pre-knitting Process

Let’s take the example with silk yarn production way to talk about pre-knititng process.

Because the silk has sericin, and high rigidity. It is easy to appear brittle broken and missing needles and other defects when weaving, so it needs to be dealt a bit before weaving.

If the twisted silk manufactured by the general polyester factory is used, it needs to go through the following processing: the twisted raw silk is placed in the solution containing softening agent (such as ENS-I) and foaming agent (such as HV-302), bath ratio 1:20, temperature 40-50℃ for 18 hours, after drying, winding, and then on the machine weaving.

If the simple raw silk directly provided by the factory is used, it is necessary to put the raw silk in a barrel in a vacuum container containing the treatment solution (generally, the solution of Swire oil with bath ratio of 1:10, 109/L) at room temperature, so that the treatment solution can quickly penetrate into the inner layer of the coil and the inside of the sericin, and the machine is woven after processing.

3, Programming

Then, deal with program design. After determining the number of nozzles and paths, the program is programmed in the special programming system according to the choice of nozzles and paths, and attention should be paid to timely refueling and air suction programming design.

The selection of nozzles should be determined according to the performance of the machine itself. The front nozzles are in the inner layer and the back nozzles are in the outer layer. When weaving the fabric covered with one material and another material, the sand nozzles should be appropriately selected according to the needs.

4, Run on the machine

After the program is prepared, the machine began to debug, in this process should strictly control the size, repeated modification of the program, until reaching the requirements.

Getting Started

Starting your seamless clothing project with us is simple and straightforward. Reach out to our team to share your design ideas and specific requirements, and we’ll guide you through every step of the process. We’ll provide a customized quote and a clear production plan, ensuring transparency and confidence from the outset. Our experts will support you from design through to delivery, leveraging cutting-edge technology and advanced seamless knitting machines to produce your garments efficiently and to the highest standards. Whether you need seamless activewear, seamless sportswear, or yoga wear, we are committed to delivering exceptional quality and service. Contact us today to take the first step toward creating your high quality seamless clothing collection.

Global Reach

As a leading seamless clothing manufacturer, our reach extends across the globe. We proudly supply high quality seamless garments to clients in Europe, America, Japan, Australia, Southeast Asia, and beyond. Our extensive network of reliable suppliers and partners enables us to deliver seamless clothing efficiently and consistently, no matter where you are in the world. This global presence keeps us at the forefront of fashion trends and new technologies, allowing us to offer innovative, stylish, and high-quality seamless apparel to brands of all sizes. Whether you are an emerging label or an established global brand, we are dedicated to supporting your growth with world-class seamless clothing solutions.