Yarn Information Guide

The concept of yarn

Yarn refers to the raw materials processed from fibers that have a certain strength, fineness, or different appearance structures, and can be of any length of fabric. They are the basic units that make up the fabric.

The role of yarn

Yarn can directly affect and determine the performance, style, and quality of a fabric by changing its structure, performance, and color. It can also be mixed, compounded, and processed in various ways to obtain an endless variety of colors. Therefore, for fabrics, especially for newly developed products, the design, variation, and application of yarns are very important, playing a crucial role in certain characteristics of the product.

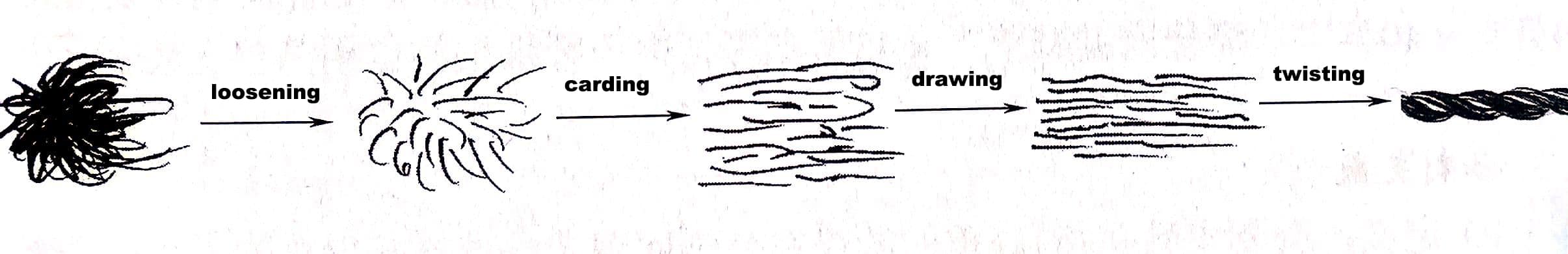

Yarn formation process

Raw fibers need to undergo several processes such as loosening, carding, drawing, and twisting to form yarns that meet weaving requirements. The process from fiber to yarn is called spinning.

- Loosening

Loosening is the process of breaking large fiber blocks into small pieces and bundles.

- Carding

Carding is the process of breaking down small pieces or bundles into a single state, breaking the horizontal connections between fibers, but it cannot be completely eliminated.

- Drawing

Drawing is the process of elongating and thinning a collection of fibers with curved and curly shapes after carding, allowing the fibers to straighten and the hooks to disappear, while also achieving a predetermined thickness.

- Twisting

Twisting is the use of rotational motion to twist and rewind a thin strip of fibers around its own axis. By friction between fibers and the pressure exerted on the inner fiber segment when the outer fiber segment rotates around the axis and is stretched, fix the longitudinal connection between the fibers inside the yarn.

Fineness of Yarn

Yarn is generally measured by fineness, which is the most important indicator of yarn. The finer the yarn, the higher the requirement for fiber quality, and the smoother and more delicate the woven fabric, the better the quality.

Fineness unit

There are four units that represent yarn fineness, namely yarn density, imperial count, metric count, and denier number. Among them, English count and metric count are weight units, and denier number and yarn density are length units.

- Yarn density

Definition: Yarn density (Tt) refers to the mass per unit length of fibers, single yarns, netting, ropes, etc. It is an indicator that describes the fineness of yarn, and its unit is represented by “tex”.

The relationship between numerical value and thickness: The higher the yarn density value, the thicker the yarn, such as 18tex yarn being thicker than 14tex yarn.

Application: Yarn density can be used to represent the thickness of all textile yarns.

- English count

Definition: The English count refers to the number of “840 yards” in a pound of cotton yarn length at a predetermined moisture regain, which is the number of English counts. It can be simply pronounced as “a few yarns”, and the unit is represented by “S”.

The relationship between numerical value and thickness: For example, a pound of cotton yarn with a length of 1680 yards, which is twice the length of 840 yards, is called a 2 English count yarn and can be written as 2S; For another example, a pound of cotton yarn has a length of 2520 yards, which is three times the length of 840 yards, and is called a 3 English count yarn, which can be written as 3S. By analogy, the larger the value before “S”, the finer the yarn; The smaller the value, the thicker the yarn.

Application: The English count is generally used to represent the thickness of cotton fabrics, cotton textiles, and other yarns.

- Metric count

Definition: Metric count refers to the number of length of 1kg yarn at a predetermined moisture regain. Abbreviated as “a few yarns”, represented by “N”.

The relationship between numerical value and thickness: For example, a 1kg weight yarn with a length of 64km is 64 metric yarns, which can be written as 64N; A 1kg weight yarn has a length of 50km, which is 50 metric yarns and can be written as 50N, and so on. The larger the value before “N”, the finer the yarn, while the smaller the value, the thicker the yarn.

Application: Generally, wool fabrics and wool blended fabrics use metric count to represent yarn thickness.

- Denier number

Definition: Denier number refers to the weight of a 9000-meter-long fiber in grams at a predetermined moisture regain. Represented by the letter ‘D’ or ‘d’.

The relationship between numerical value and thickness: for example, a polyester filament with a length of 9000m and a weight of 120g is 120 deniers, and for example, a nylon filament with a fineness of 150 deniers represents a nylon filament with a length of 9000m and a weight of 150g. The larger the number before “D”, the thicker the fiber, while the smaller the number, the thinner the fiber.

Application: “Dan” is usually used to indicate the thickness of filaments, including natural and synthetic filaments.

Conversion of fineness units

1S=1.69N

1N=0.59S

Tt=583.1/S

Tt=1000/N

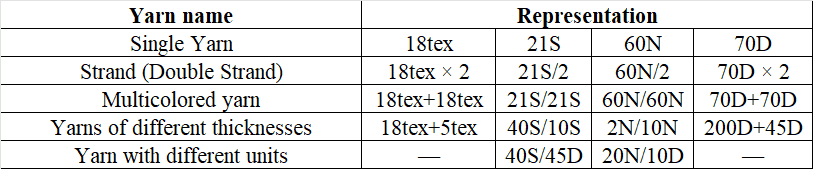

Method for expressing yarn fineness

- Single yarn

Single yarn is a single product formed by the spinning process of fibers.

- Stranded yarn

Stranded yarn refers to a yarn composed of two or more single yarns that are crossed and folded together.

- Multicolored yarn

Multi-colored yarn refers to two single yarns of the same thickness and different colors that are folded together.

- Yarns of different thicknesses

Yarn with different thicknesses refers to two single yarn strands with the same unit but different thicknesses, known as coarse and fine yarns.

- Yarn with different units

Different units of yarn refer to the intersection and merging of two different units of yarn, such as a cotton yarn and a polyester filament.

Yarn fineness & Clothing

- Fineness and fabric appearance

The finer the yarn, the higher the requirements for fiber raw materials. Generally, slender fibers such as long-staple cotton, fine velvet cotton, and merino wool can be spun to produce a fine yarn. The appearance of fine yarn fabric is delicate, smooth, and with less hairiness, and the fabric is flat and delicate, with a sense of luxury and lightness. The thicker the yarn, the more fluffy and thick the fabric, giving it a warm feeling.

- Fineness and clothing style

The clothing made of fine yarn fabric has a delicate, exquisite, and delicate feeling, reflecting a fine and lightweight clothing style. The clothing made of roving fabric has a rough, casual, natural, and convenient feeling, reflecting a relaxed and thick clothing style.

- Fineness and fabric texture

The same fiber material, the finer the yarn, the softer and smoother the feel, and the better the drape, making it more comfortable. The same cotton fiber fabric, the 80 S double-stranded shirt fabric is smoother and softer than the 7 S denim fabric. However, fabrics with coarse yarns have better elasticity than those with fine yarns, and the fabric also has better wrinkle resistance.

- Fineness and Fabric properties

(1) Fineness and fabric warmth retention. Generally speaking, the finer the yarn of a fabric, the closer the fiber holds, the smaller the gap, the less air content, and the poor warmth retention; The yarn is coarse, with large gaps, high air content, and good warmth retention of the fabric.

(2) Fineness and fabric pilling performance. Fine yarn fineness, long fiber length, tightly packed fibers, less surface hairiness, and less prone to pilling and pilling; The yarn is thick, the fiber is short, and the surface has a lot of hairiness, which is easy to pilling and pilling.

- Fineness and Fabric cost

The finer the fabric yarn, the higher the fiber grade required and the more expensive the price; The finer the yarn, the longer the processing techniques such as carding, stretching, and twisting, the more expensive the cost, and the higher the price; The finer the yarn, the more pieces of fabric, and the more expensive the weaving cost. So fabrics made of the same raw material have similar thickness, and the price difference between high tex and low tex fabrics is significant. A 60S double layered T-shirt is much more expensive than a 30S single yarn T-shirt.

Yarn Twist

Twisting

When fibers are spun into single yarns and combined into strands, twisting is used to rotate the single yarn of the fiber bundle in one direction, in order to make the fibers tightly fit, increase fastness, elasticity, and smoothness. The effect of twisting can also make the previously unsoft luster of the fibers become orderly and consistent, enhancing the reflectivity of the yarn.

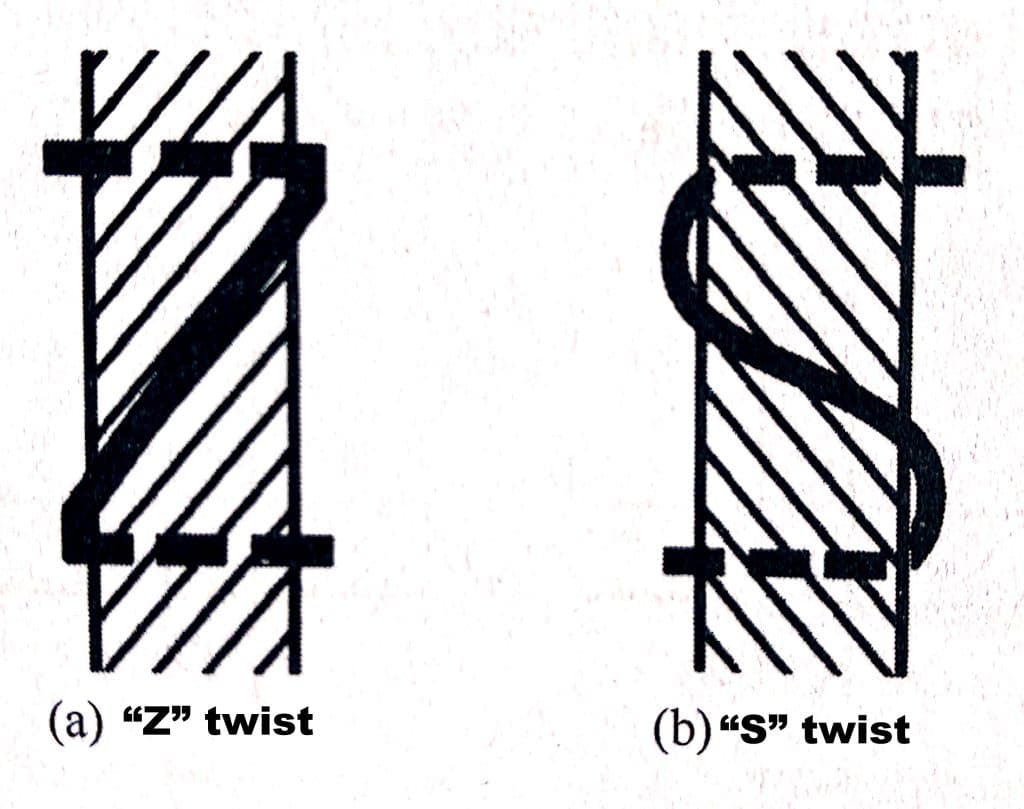

Twist direction

- Definition

Twist direction is the direction in which the yarn rotates during twisting.

- “Z” twist and “S” twist

Twisting has directionality, one is from bottom to top, from left to right, called backhand twisting or left hand twisting, also known as Z-direction twisting, abbreviated as “Z” twisting; The other type is from bottom to top, from right to left, called forehand twisting, right hand twisting, also known as S-direction twisting, abbreviated as “S” twisting.

Twist

- Definition

Twist refers to the average number of twists per unit length of yarn. That is the number of turns of yarn per unit length.

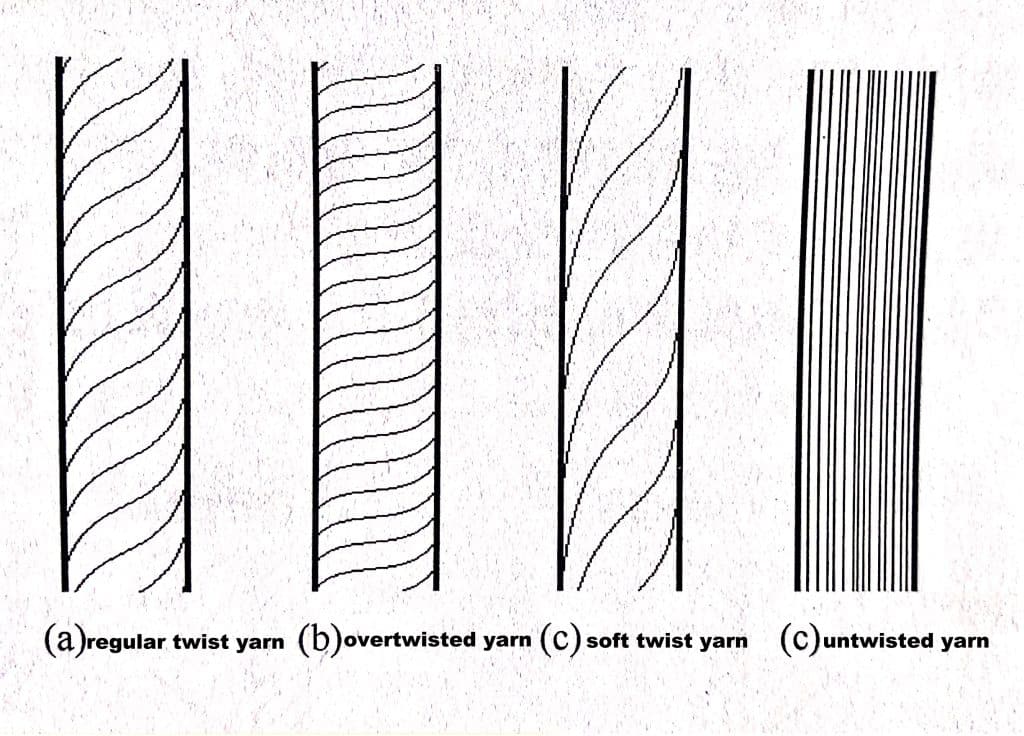

- Regular twisted、Overtwisted、Soft twist、Untwisted

Usually, the normal twist of different yarns is specified and referred to as regular twist yarn; And those with a twist greater than that of regular twist yarn are called overtwisted yarn; A yarn with a twist less than that of a regular twist is called a soft twist yarn; Twistless yarn is called untwisted yarn, which has less twist or even no twist than soft twisted yarn.

- Impact on fabrics

The twist of the yarn has a significant impact on the fabric. Twist can affect the appearance, feel, wearing comfort, and warmth of fabrics.

(1) Regular twisted yarn. Regular twist yarn refers to yarn with normal twist. That is to say, the yarn is well held, with a comfortable feel, a smooth surface, good reflection, and a strong twist that meets the basic requirements of weaving, clothing production, and wearing. The fabric of general clothing is woven with regular twisted yarn, such as plain cloth, poplin, khaki, and gabardine.

There are two types of regular twisted yarn: organic woven yarn and knitted yarn. The twist of woven yarn is slightly higher than that of knitted yarn, and the strength is also slightly higher than that of knitted yarn. The hand feel is not as soft and fluffy as that of knitted yarn.

(2) Overtwisted yarn. Overtwisted yarn refers to yarn with a twist greater than normal. The higher the twist of the yarn, the tighter the grip, and the greater the strength. The finer the particles on the surface of the yarn, the weaker the reflection. The greater the twist, the harder and more transparent the feel.

Overtwisted yarn is generally used for thin fabrics in summer. Thin fabrics have fine yarn, thin density, and a soft feel, making the fabric easy to fit and causing discomfort. By increasing the twist of the yarn, thin fabrics can be made comfortable to wear. For example, crepe fabric, chiffon, georgette, double crepe, smooth crepe, crepe satin, etc., all use strong twist yarn, making them ideal clothing fabrics for summer. In summer knitted clothing, the method of increasing yarn twist is also used to develop cool T-shirts.

(3) Soft twist yarn. Soft twist yarn refers to yarn with less than normal twist. The twist of the yarn is small, the cohesion between fibers is small, the yarn is loose, the internal stress is small, the feel is soft, the canopy is loose and warm, the twist of the yarn is small, and the surface particles increase, which can produce a special appearance. But the twist of the yarn is small, and the fiber hairiness is easy to protrude, causing pilling and pilling.

Soft twist yarn is generally used in fabrics with a fluffy appearance, such as plush fabrics, coarse woolen fabrics, all cotton flannel fabrics, etc. Soft twist yarn is used in the weft direction, making it easy to pile up and the fabric soft and fluffy; Chemical fiber wool-like fabrics sometimes use slightly lower twist yarns to enhance the texture of the fabric (but are prone to pilling and pilling). Some multi-color patterned fabrics use weak twists when doubling, increasing the contrast between two different colored single yarns and creating a unique appearance.

(4) Twistless yarn. Twistless yarn refers to yarn with very little or no twist at all. Short fibers must be twisted in order for the yarn to form. When single yarns are folded together, untwisted yarns are sometimes used to create a cloud like appearance when weaving two single yarns randomly up and down, which is very creative; Long filament yarn has no luster and can enhance the luster of the fabric, making it soft to the touch. For example, various satin fabrics use untwisted long filament, resulting in a bright and smooth fabric surface.

Yarn Shape

- Staple yarn

Definition: Staple yarn refers to various yarns made by spinning technology, with fiber lengths similar to cotton, linen, wool, etc., typically ranging from tens of millimeters to hundreds of millimeters.

Features: The parallelism of staple yarn is relatively poor, with hooks, folds, loops, entanglements, etc. inside the fibers, and the yarn structure is relatively simple. The strength of staple yarn is related to the friction and cohesion coefficient of the fibers, and the overall utilization rate of fiber strength is not as good as that of filament; The unevenness of yarn is relatively high (including strength, twist, and weight); The gap between fibers is larger than that of filaments, and the fluffiness is also greater; The yarn has a large diameter, low density, and good moisture absorption and breathability.

- Filament yarn

Definition: Filament yarn refers to yarn that is continuous like silk and has a fiber length of over 800m. Among natural fibers, only silk is in the form of long filaments, while most chemical fibers can be made into long filaments first, and then changed or cut into other fiber forms as needed.

Features: The fibers of filament yarn are highly parallel and tightly arranged, with strong regularity in fiber arrangement. The yarn structure is monotonous, and the twist is generally less. High utilization rate of filament yarn fiber strength; Small yarn diameter, high density, and low fluffiness; The mechanical properties of the yarn are relatively uniform; The bending stiffness of yarn is high.

- Textured yarn

Definition: Textured yarn refers to a chemical fiber filament that undergoes two or three degrees of spatial curling and deformation, and is fixed by appropriate methods to disrupt the parallel state of the original fibers, becoming a silk strip with a considerable degree of bulkiness and elasticity. Its appearance and certain characteristics, such as the yarn form of short fiber yarn. Textured yarn is a significant achievement in imitating short fibers and various natural fibers with synthetic filaments.

Features: Textured yarn shortens and naturalizes long filament fibers, and achieves many excellent properties of short fiber yarn. Such as fluffiness, softness, soft luster, water absorption, warmth retention, lightweight, and no wax like sensation, there are also some properties that are far superior to short fiber yarn, such as stretchability, elasticity, etc.

Most textured yarns are made of polyester and nylon, and sometimes acrylic and polypropylene are also used. Textured yarn makes it easy for chemical filaments to imitate short fibers, without the need to cut the filaments and use the spinning process of short fibers to complete. Directly made from filament is a simple process of imitating staple fibers with filament. There are mainly several types of textured yarn, including elastic type, expanded type, and improved elastic type, and later on, there were patterned yarn products with textured yarn.

- Bulk yarn

Definition: There are two types of bulky yarn: short fiber bulky yarn and filament bulky yarn, generally referring to short fiber bulky yarn. Bulky yarn is a mixture of high shrinkage fibers and low shrinkage fibers during spinning. When high shrinkage fibers contract with heat, the low shrinkage fibers curl up, thereby increasing the volume of the yarn and obtaining bulky yarn. The main raw material for bulky yarn is acrylic fiber.

Features: The main characteristics of bulky yarn are as follows

① Structure. Bulky yarn has a large volume, a fluffy structure, and a diameter that can be increased by more than twice; Tight inside and loose outside, high shrinkage fibers extend straight into the yarn core, and generally fibers curl outside; Length shrinkage.

② Performance. Expanded yarn has an increased volume, smaller volume and weight, and lighter weight; Soft and fluffy to the touch, with an excellent hairline appearance; Low strength, easy to deform; When mixed with natural fibers, the appearance of natural fibers can be obtained; The yarn core is sturdy, with good coverage, low thermal conductivity, good warmth retention, good insulation, and good drape; Excellent wear resistance, improved hygiene (good moisture absorption and dissipation), and soft luster.

- Profile fiber yarn

Definition: Profile fiber yarn refers to various yarns spun from shaped fibers, including short fiber yarn, filament yarn, and ultrafine yarn.

Features: The main characteristic of profile fiber yarn is that the luster and feel of the yarn are significantly different from conventional yarns. Some have a particularly bright luster, such as irregular silk organza; Some biomimetics is particularly realistic, such as imitation mohair, imitation of various animal fur, etc.

- Superfine fiber yarn

Definition: Superfine fiber yarn refers to various yarns spun from ultra-fine fibers.

Features: The fineness of superfine fiber far exceeds that of ordinary fibers, including natural fibers. Their fabrics have significant advantages such as a soft feel, good water absorption performance, and good coverage performance.