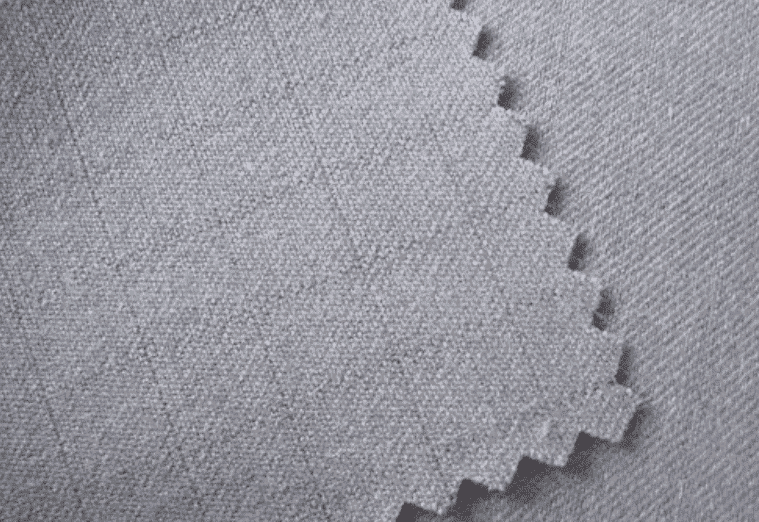

Introduction to Textile Fibers

Fibre

People usually refer to fine substances with a length greater than a thousand times the diameter (only a few micrometers or ten micrometers in diameter) and certain flexibility properties as fibers, such as cotton fibers, hemp fibers, glass fibers, hair fibers, etc.

Textile fibers

Textile fibers refer to fiber raw materials that meet the basic conditions of textile products.

The raw fibers need to go through various processes such as loosening, carding, stretching, twisting, warping, weaving, finishing, and stretching to make textile products. Then, they undergo various clothing production processes such as spreading, cutting, sewing, and ironing to make various types of clothing. Wearing on the human body requires meeting the requirements of stretching, friction, flexion, warmth preservation, coverage, comfort, aesthetics, and other aspects during human movement. Therefore, textile fibers must meet the following basic conditions.

Necessary conditions for textile fibers

- Has certain mechanical properties

- Has a certain degree of fineness and length

- Has a certain degree of elasticity and plasticity

- Has a certain degree of insulation

- Has a certain degree of moisture absorption

- Has certain chemical stability

- Has a certain degree of spinnability

Classification of Textile Fibers

There are many types of textile fibers, and people are constantly exploring new and better textile fiber raw materials. However, we can still classify textile fibers based on their sources or properties, in order to have a more intuitive and comprehensive understanding of textile fiber raw materials.

Composition of commonly used textile fibers

- Natural fiber

Natural textile fibers refer to fiber raw materials that exist and grow in nature, have textile value, and can be directly used for textiles. At present, the most commonly used natural fibers include cotton, linen, silk, wool, etc.

- Chemical fiber

Chemical fibers refer to various fiber raw materials processed from natural or artificial polymer materials. Chemical fibers can be divided into regenerated fibers and synthetic fibers based on different sources of raw materials.

- Difference

The biggest difference between natural fibers and chemical fibers is that their morphology is relatively fixed and single; The morphology of chemical fibers is rich and varied.

Because natural fibers are ‘grown’ and are more constrained by natural conditions, their changes are limited; Chemical fibers are “made”, so under certain technical conditions, they can be easily changed in length, fineness, cross-section, appearance, etc. according to human preferences, making clothing more diverse and diverse.

Comparison of textile fiber properties

- Performance characteristics of natural fiber

Natural fibers generally have good moisture absorption, are comfortable and breathable to wear, are not prone to static electricity, shrink when washed, mold and decay, and are not as strong as synthetic fibers. They do not have thermoplastic properties and cannot be shaped in one go.

(1) Plant fiber performance characteristics: high density, heavy sensation, poor elasticity, and easy wrinkling; Alkali resistant but not acid resistant, suitable for general detergents; It is easy to mold under humid and hot conditions.

(2) Animal fibers performance characteristics: relatively low density and light sensation; Elasticity (in a dry state) is relatively good and not prone to wrinkles, especially for wool, which has good elasticity in both quick and slow stages; Acid resistant but not alkali resistant, neutral or weakly acidic detergents should be used when washing: they are prone to be eaten by insects in environments that are not clean enough.

- Performance characteristics of chemical fibers

Regenerated fibers and synthetic fibers are both processed using chemical methods, resulting in rich and diverse forms. But their raw materials come from different sources and their fiber properties are different.

(1) Performance of recycled fibers: The raw materials of recycled fibers are derived from natural cellulose and protein, so their performance is similar to that of natural fibers, such as good moisture absorption performance, and good wearing comfort, but not thermoplastic performance

(2) Performance of synthetic fiber: Synthetic fibers are made from synthetic polymer compounds that exhibit some unique commonalities. Such as high strength, good elasticity, no mold or decay, easy to generate static electricity due to friction, easy to stain, etc. The biggest difference in performance between synthetic fibers and natural fibers is their poor moisture absorption and thermoplastic properties.

Common Textile Fibers

-

Cotton fiber

Cotton fiber is the fiber that removes cotton seeds, known as lint or raw cotton, and is an important raw material for textiles. According to the thickness, length, and strength of fibers, raw cotton can generally be divided into the following three categories.

(1) Long staple cotton. Long staple cotton, also known as island cotton, is a slender, mercerized, and high-strength cotton fiber that is an important raw material for spinning high-end and special cotton textiles.

(2) Fine velvet cotton. Fine velvet cotton, also known as upland cotton or plateau cotton, is a widely used natural textile fiber that is widely planted and produced in the world.

(3) Coarse cotton. Coarse cotton, also known as Asian cotton. Coarse plush cotton fibers are thick, short in length, and have good elasticity, making them suitable for making velvet yarn, making-velvet-like fabrics, or wadding.

-

Hemp fiber

Hemp fibers are fibers obtained from various hemp plants, including bast fibers and leaf fibers. Hemp fiber is one of the earliest textile materials used for clothing by humans. There are many varieties of hemp fibers, including ramie, linen, jute, hemp, apocynum, and sisal, which are often used as clothing and textile materials.

(1) Ramie. Ramie is the most excellent textile material among hemp fibers. Ramie fiber is relatively thick and long in length, making it a finer spinning thread and a more high-end raw material for hemp fabrics. Ramie fibers can be either pure spun or blended and can be used together with polyester blended linen to make summer clothing. They are lightweight, cool, crisp, not snug, breathable, and easy to wash. Ramie fiber has a harder feel and more yarn hairiness.

(2) Flax. Flax is also the most excellent textile material among hemp fibers. The length of flax fiber is shorter than that of ramie fiber, and the fineness is finer than that of ramie fiber. Flax fibers have a rougher and harder feel than cotton fibers but are softer than ramie fibers. Excellent linen fiber fabric is a very high-end textile. Flax fibers can be pure or blended, usually mixed with ramie, cotton, and chemical fibers. They are excellent clothing materials and are also fabrics for embroidery or embroidery clothing.

(3) Other hemp fibers. In addition to the most commonly used ramie and flax fibers, the hemp fibers used in clothing materials include apocynum, jute, hemp, etc. Apocynum fiber is relatively soft and has health value; Jute, hibiscus, and other fibers are thicker but have good moisture absorption and breathability, making them suitable as packaging materials; In addition to blending hemp with jute as packaging material, some countries also develop it into clothing fabrics.

-

Silk fiber

Silk fibers are the only long fibers in natural fibers and can generally be between 800-1100m in length. They are the main raw materials for silk and satin. Silk fiber comes from tussah, mulberry, castor, cassava, and other silkworms, with mulberry having the best quality.

(1) Mulberry silk. Mulberry silk, also known as real silk, is a high-end textile raw material. According to different processing methods, it can be divided into two types: raw silk and cooked silk. Raw silk is hard, cooked silk is soft. Raw silk is unrefined silk, that is, silk that has not undergone any treatment after reeling. Silk reeled using local methods is called earthen silk (which has been basically eliminated); Silk reeled using improved methods (semi-mechanized) is called industrial and agricultural silk. Ripe silk refers to refined silk.

(2) Tussah silk. Tussah is a wild silkworm that feeds on oak leaves. The color of tussah is yellow-brown. This brown pigment is difficult to remove, making it difficult to dye beautifully, which affects its value in use.

(3) Double Palace Silk. Double palace silk is made from double palace cocoons. A double palace cocoon is a cocoon made by two silkworms, with two silk heads intertwined in a disorderly manner. The silk drawn out varies in tension and thickness, and there are many small knots on the silk. However, it is precisely due to this disadvantage that this type of silk fabric is thick, unique, and very popular in the market.

(4) Spun silk. Spun silk is made from waste silk, cocoons, cocoon clothing, and other raw materials, processed into short fibers, and then spun into yarn through the spinning process. Spun silk has excellent luster, uniform thickness, and good strength and elongation. Due to its use of short fibers for weaving, the silk strip has a lot of air inside, good insulation performance, and good moisture absorption, making it suitable for use as pajama fabric. However, its disadvantage is that it is prone to hair after multiple washes.

-

Hair fiber

Hair fiber refers to the fiber material obtained from various animals and used for weaving. Natural hair fibers include sheep hair, cashmere, camel hair, yark hair, etc. Sheep wool and cashmere are the most commonly used fabrics in clothing.

(1) Sheep wool. Wool often refers to sheep wool in textiles. Sheep wool is produced in various countries around the world and is usually divided into several categories based on fineness and length, such as fine wool, long wool, hybrid wool, and coarse wool. Among them, fine wool – Australian Merino wool is the thinnest and of the best quality, with a diameter of 25 μ Below m. Fine wool has a uniform texture, soft and elastic feel, soft luster, and a length of 50-120mm. The curl is dense and uniform, and the spinning performance is excellent.

(2) Cashmere. Cashmere is a valuable textile material obtained from the bodies of cashmere goats and goats that can handle cashmere. The diameter of cashmere fibers is finer than that of fine wool. Most cashmere is produced in Inner Mongolia, Xinjiang, Liaoning, Shaanxi, Gansu, Shanxi, Ningxia, Xizang, Qinghai and other places in China. Its annual output accounts for about 50% of the world’s total output, ranking first in the world, and its quality is also the best. The products spun from cashmere mainly have the characteristics of being fine, light, soft, warm, and smooth. The textiles produced, such as cashmere sweaters, cashmere coats, and cashmere tweeds, are all high-end and valuable commodities and are deeply welcomed in the international market.

In addition, mohair, alpaca hair, and other excellent wool fibers are commonly used in knitted sweaters, coats, and other clothing. Camel hair has good warmth retention and is often used as a filling material for winter clothing.

-

Regenerated fiber

Regenerated fibers refer to textile fibers made from natural polymer compounds such as cellulose and protein, which are chemically processed into concentrated polymer solutions, and then spun and post-treated. Regenerated fibers can be divided into two categories: regenerated cellulose fibers and regenerated protein fibers. The main products of regenerated cellulose fibers are viscose fiber, as well as copper ammonia fibers, acetate fibers, etc. Environmentally friendly regenerated cellulose fibers include Tencel and Modal. Regenerated protein fiber, also known as artificial wool, has fewer varieties.

(1) Viscose fiber. Viscose fiber is a major variety of artificial fibers, made from natural cellulose, cotton lint, wood, and other raw materials. According to the different forms of fibers, there are artificial cotton, artificial wool, artificial silk, etc. Viscose fibers have a soft feel and good luster; Excellent moisture absorption and breathability performance; Colorful and full-color spectrum. However, it is prone to wrinkling and has poor elasticity, low wet strength, and is not washable. It is slightly less acid and alkali-resistant than cotton.

(2) Tencel fiber and modal. Tiansi Fiber is an environmentally friendly type of regenerated cellulose fiber, processed from wood as raw material. The recovery rate of chemical agents in production can reach 99%, minimizing environmental pollution during the production process. The wrinkle resistance and strength of the fabric have been greatly improved compared to the original product.

Modal is also an environmentally friendly regenerated cellulose fiber, which has low environmental pollution during the production process. The wrinkle resistance and strength of the fabric have been improved compared to the original product.

-

Synthetic fiber

Synthetic fibers refer to chemical fibers made from artificially synthesized polymer compounds through spinning and post-processing. The most commonly used synthetic fibers in clothing are polyester, nylon, and acrylic. The main varieties of synthetic fibers include polyester, nylon, acrylic, polyvinyl alcohol fiber, polypropylene fiber, polyvinyl chloride fiber, spandex, etc.

(1) Polyester. Polyester was officially put into industrial production worldwide in 1953 and is still a relatively young variety among synthetic fibers. However, due to its easy availability of raw materials, excellent performance, wide range of applications, and rapid development, its production has now ranked first among chemical fibers.

The biggest characteristic of polyester is its good elasticity, which is stronger than any commonly used fiber. Therefore, polyester fabrics are flat, straight, and not easily deformed, earning the reputation of being iron-free. Polyester also has good strength and wear resistance. The fabric woven from it has a fastness of 3-4 times higher than other fibers, making clothing durable. Polyester also has strong heat resistance. After 20 days at a temperature of 100 ℃, its strength remains undamaged; After 80 days of testing at a high temperature of 130 ℃, the strength only decreased by 25%. The ironing temperature of polyester is below 150 ℃. Polyester has good chemical stability. Under normal temperature, it will not react with weak acids, bases, or oxidants. If 37% concentrated hydrochloric acid is used to react with it for six weeks, there is still no loss in fiber strength. But under the action of strong alkali, especially at high temperatures and for a long time, it can cause the decomposition of polyester. However, this effect is gradually carried out from the surface of the fiber inward, and the interior will not be significantly damaged.

Due to its smooth surface, tightly arranged internal molecules, and lack of hydrophilic structure between molecules, polyester has poor moisture absorption and a moisture regain of only 0.4%. The fabric woven from it feels stuffy and breathable when worn on the body. In addition, due to the smooth surface of the fibers and the poor adhesion between them, the areas where they are frequently rubbed are prone to fuzzing and pilling, and the fuzzing areas are prone to dirt accumulation; Once dirt seeps into the interior of the fabric, it is difficult to clean, so it is necessary to wash it regularly.

(2) Nylon. Its scientific name is polyamide fiber, and due to the different structures of amide molecules, there are also different products, such as nylon 66, nylon 1010, nylon 6, etc. Nylon is the earliest synthetic fiber variety in the world. Due to its excellent performance and abundant raw material resources, it has always been the variety with the highest yield of synthetic fibers. It was not until 1970 that nylon ranked second in synthetic fibers due to the rapid development of polyester.

The biggest characteristic of nylon is its high strength and good wear resistance, ranking first among existing synthetic fibers in terms of strength and wear resistance. According to measurements, its wear resistance is 20 times that of wool and 10 times that of cotton. Compared to viscose fibers, it is 10 times higher in the dry state and 140 times higher in the wet state. Its strength is outstanding, such as using nylon thread to twist into a rope that can lift a 4-ton car with a full load of goods. Mixing it with adhesive fibers is as strong as adding steel bars to cement, indicating its high strength.

Its drawbacks are similar to polyester, with poor moisture absorption and permeability, a moisture regain of 4%, and a tendency to generate static electricity in dry environments. Short fibers are also prone to pilling and accumulation of dirt, but they are easy to clean and dry quickly after washing. In addition, the heat and light resistance of nylon is not good enough, and the clothing made from it is prone to discoloration, graying, and yellowing, which is not as beautiful as polyester. The ironing temperature of nylon should be controlled below 140 ℃. At the same time, nylon has poor shape retention, and clothes made from it are not as straight as polyester and are prone to deformation.

(3) Acrylic fiber. Acrylic fiber has a white appearance, and a curly, fluffy, and soft feel, resembling wool. It is often used to blend with wool or as a substitute for wool, hence it is also known as synthetic wool.

Acrylic fiber has the best light resistance among chemical fibers. Natural silk and viscose silk are exposed to sunlight for 300 hours, resulting in a 75% strength loss; Cotton is exposed to 500 hours of sunlight, resulting in a strength loss of 74%; Acrylic fiber, on the other hand, has a strength loss of no more than 20% when exposed to sunlight for 1000 hours. The acrylic fabric has a bright color and is not easily faded. The density of acrylic fiber is 1.14-1.17g/cm ³, It is 10% lighter than wool and 20% lighter than cotton, with a light and sturdy texture. Acrylic fiber has excellent elasticity and warmth retention. Its elasticity is close to that of wool, and its warmth retention is 15% higher than that of wool. Acrylic fibers have a certain resistance to inorganic and weak acids; The fabric made of acrylic fiber has good pleating retention performance and is neat when processing clothing.

The wear resistance of acrylic fiber is one of the worst among synthetic fibers, and the pleats of acrylic clothing are prone to wear and breakage; The moisture absorption of acrylic fiber is not good enough, with a moisture regain of 2%, but its wettability is better than that of wool and silk fibers. The ironing temperature of acrylic fiber is below 130 ℃.

(4) Vinylon. Vinylon is as white as snow and as soft as cotton, making it often used as a substitute for natural cotton. People call it synthetic cotton. Vinylon has a moisture absorption performance of up to 5% (cotton is 7% -8%, while polyester is only 0.4%), making it the best synthetic fiber in terms of moisture absorption performance. Secondly, it has good wear resistance, light resistance, and corrosion resistance.

Vinylon has a leather core structure (like the wooden core layer of a pencil), which poses significant difficulties in dyeing. It has poor resilience, so the fabric produced by it is prone to wrinkles. In addition, Vinylon has one major characteristic: strong dry heat resistance and extremely poor wet heat resistance. In a dry and hot environment, when the temperature reaches 150 ℃, the strength of the vinylon textile fabric is not affected after being treated for 2 hours; When placed in water at 80 ℃, the strength of vinylon decreases by 60%. When the water temperature exceeds 110 ℃, the fabric will harden and deform. Currently, Vinylon products are rarely used in clothing.

(5) Polypropylene fiber. Polypropylene is one of the youngest varieties of synthetic fibers

The density of polypropylene fiber is 0.90~0.91g/cm ³, Smaller than water. It has a high rebound force, and its elastic recovery rate can reach 96%~100% when extended by 5%, making the fabric with polypropylene fiber composition firm and elastic. In addition, it also has good warmth retention, water resistance, and corrosion resistance.

Due to the lack of hydrophilic structure in polypropylene molecules, its moisture absorption rate is extremely low. Under standard conditions (temperature 20 ℃, relative humidity 65%), it is almost non-hygroscopic, and the moisture regain of polypropylene is 0, but it has good moisture conductivity. Clothes made of polypropylene fiber are breathable and feel stuffy when worn, but the fabric has a low shrinkage rate and is easy to wash and dry.

The light and heat resistance of the third wheel are poor, and the ironing temperature should not exceed 100 ℃; Polypropylene also has a poor feel and is not easy to dye. Polypropylene is less commonly used in clothing and is often used in fillers and carpets.

(6) Polyvinyl chloride fiber. Most of the plastic raincoats, plastic shoes, and other materials we come into contact with in our daily lives belong to this type of raw material.

Polyvinyl chloride fiber has many advantages, such as strong chemical corrosion resistance and easy preservation; The thermal conductivity is worse than that of wool, and the insulation is strong; High electrical insulation, and difficult to ignite. In addition, Polyvinyl chloride fiber has a prominent advantage. The underwear woven from it can treat rheumatoid arthritis or other injuries without causing irritation or damage to the skin. Because it has no hydrophilic structure on its molecules and a moisture regain of 0, this type of underwear is worn on the body. After multiple frictions, static electricity is generated and gradually accumulates on clothing. Even if the relative humidity of the air reaches 80%, electrons are still difficult to flow, resulting in the loss of charge. Due to the effect of static electricity, pure spun Polyvinyl chloride fiber clothing has a relatively therapeutic effect on rheumatoid arthritis.

The disadvantage of Polyvinyl chloride fiber is quite prominent, which is its poor heat resistance. When the water temperature is 70 ℃, the fibers begin to contract and soften. When the temperature exceeds 70 ℃, the clothes will shrink into a ball and become hard. Polyvinyl chloride fiber clothing can only be washed in water temperatures below 30-40 ℃. Polyvinyl chloride fiber is now less commonly used in clothing.

(7) Spandex. The scientific name of spandex is polyurethane elastic fiber. It is a chemical fiber with special elastic properties, which has been industrialized and has become the fastest-developing elastic fiber.

Spandex and latex fibers have similar properties, with an elongation of up to 500% -700% and a rebound rate of 97% -98%, resulting in excellent elasticity. However, the strength of spandex is 2-3 times higher than that of latex yarn, with finer fineness and better resistance to chemical degradation. Spandex has good acid and alkali resistance, sweat resistance, seawater resistance, dry cleaning resistance, and wear resistance, with a moisture regain of 0.

The content of spandex in fabrics is relatively low, generally ranging from 3% to 12%. Spandex mainly exists in the form of core-spun yarn in fabrics or is made into textured yarn with spandex to weave elastic fabrics. Common examples include elastic jeans, elastic underwear, elastic swimwear, etc; It is widely used in sock cuffs, gloves, necklines, and cuffs of knitted clothing, as well as in the tight parts of space suits.

New Textile Fibers

In addition to commonly used textile fibers, people have been trying to develop better and more new textile fiber materials to meet the needs of contemporary people for clothing. Synthetic fiber clothing should have comfortable wearing performance similar to natural fibers; Natural fiber clothing should be as straight, non-shrinking, non-moldy, non-aging, and non-deformed as synthetic fibers; There are also novel fiber materials, environmentally friendly fiber materials, healthy fiber materials, and special functional fiber materials that people are looking forward to, creating, researching, and developing. Clothing needs to be updated, changed, and meet people’s expectations. The progress of textile clothing fabrics and garment accessories is a prerequisite, and textile clothing fabrics and garment accessories must achieve new, unique, and excellent results without the particularity of new fibers, especially the development of some contemporary high-tech fiber products, differentiated fibers, and high-performance fibers.

Differentiated fiber

The so-called differentiated fibers refer to various fiber materials that are different from conventional fibers. These fibers differ significantly from conventional fibers in terms of morphology, surface characteristics, internal structure, physical properties, mechanical properties, and chemical properties, and can achieve new and better results.

In recent years, differentiated fibers have developed rapidly, especially in the field of chemical fibers, which account for an increasing proportion and play a significant role, in attracting people’s attention. To understand the new types of clothing materials, it is first necessary to understand differentiated fibers.

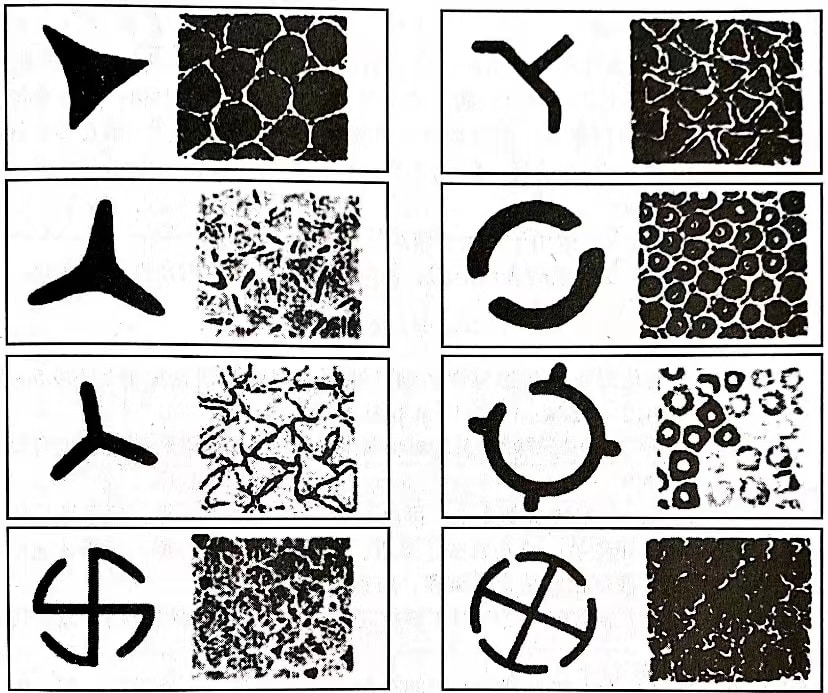

- Irregular cross-section fiber

Function: Irregular cross-section fibers may seem simple, but the effect is quite magical. Triangular cross-section fibers can make fabrics shiny, smooth, elastic, firm, wrinkle resistant, and warm; The trilobal section can achieve good adhesion, wear resistance, fluffiness, and a sense of thickness, and is not easy to pilling; The five-leaf and eight leaf cross-sectional fibers have the effects of soft luster, fluffiness, anti-pilling, and good breathability; The flat cross-section fibers are smooth and straight, not easy to tangle, and their fabrics have characteristics such as a woolly texture.

Application: Irregular cross-section fibers are commonly used in biomimetic weaving species, such as triangular cross-section fibers used for imitating silk, pentagonal cross-section hollow fibers used for imitating wool, cross cross-section fibers used for imitating linen, polygonal cross-section fibers used for imitating linen, dumbbell cross-section fibers used for imitating rabbit hair, etc., all of which have very good effects and have made great progress compared to conventional fibers.

- Microporous and porous fibers

Function: Micropores and porous fibers can prevent light reflection, making the fabric shiny and soft; It can increase the absorption of light and improve the dyeing depth; It can absorb more water and improve the moisture absorption of synthetic fibers. They have good quick drying and breathability, and can also improve dirt absorption and anti-static properties; Inflatable micropores also help to keep warm, and the density of fibers is small, making the fabric soft and warm.

Application: This technology has been applied to fibers such as polyester and acrylic.

- Fine denier fiber

Function: Fine denier fibers have low bending stiffness and can be woven into very soft and lightweight fabrics, such as eyewear, coral velvet, and particularly tight, soft, and delicate windbreaker fabrics.

Application: This type of fiber is now widely used in fine, ultra-high density fabrics, waterproof and breathable fabrics, as well as synthetic silk and other textile species

- Composite fiber

Types: ① According to the cross-sectional structure, it can be divided into double-layer fibers and multi-layer fibers. Double-layer fibers include parallel type, slanted type, skin core type, and eccentric type; Multilayer fibers include parallel multi-layer, radial, multi-core, wood grain, block type, island type, nebula type, etc.

② According to functional purposes, it can be divided into spontaneous curling fibers, segmented fibers, conductive fibers, photoconductive fibers, etc. Spontaneously curled fibers are used for weaving fabrics, bedding, carpets, and stockings. Segmented fibers are used for filamentous fabrics, ultra-fine fibers, synthetic suede, plush fabrics, non-woven fabrics, and synthetic leather. Conductive fibers are used in carpets, woven fabrics, and industrial materials. Photoconductive fibers are used in optical communication, optoelectronics, and medicine.

Function: Composite fibers can combine the characteristics of two or more types of fibers, as well as achieve functions such as high curling, high elasticity, easy dyeing, flame retardancy, and anti-static properties

- Combined filament yarn

Function: Combined filament yarn is a fancy yarn made from multifilament, textured yarn, or synthetic fiber yarn with different compositions, sizes, cross-sections, glosses, colors, polymerization degrees, and shrinkage rates of the original yarn, which is folded and twisted in various forms. They can undergo various changes during processing such as anti-spinning, stretching, deformation, twisting, and spinning.

Application: There are many varieties and variations of blended fibers, with a unique style, which adds a new approach to the development of new clothing fabrics.

- Differentiated dyeable fiber

Function: Differentiated dyeable fibers can expand the dyeable range of fibers, can be dyed at room temperature and pressure, and can be processed using general matching dyeing. It can also achieve multi-color effects, making the processing of dyed products simpler.

Application: Currently, the successfully developed differential dyeable fibers include cationic dyeable polyester, normal temperature and pressure dyeable polyester, differential dyeable nylon, acid dye dyeable acrylic, polypropylene, etc.

- High shrinkage fiber

Function: This fiber can achieve properties such as fluffiness, elasticity, thickness, insulation, lightness, wooliness, and fancy effects, which are extremely effective in improving and changing the style of products. It is a very useful raw material for developing new products.

Application: It is widely used in fabrics such as bulky yarn, wool-like fabric, bamboo slub yarn, fur-like fabric, loop-like fabric, crepe-like fabric, tufted fabric, and non-woven fabric.

- Modified fiber

Function: By chemical modification, difficult-to-dye fibers become easier to dye; Fibers with poor hygroscopicity have good hygroscopicity; Fibers with poor elasticity and easy wrinkling can maintain a flat and straight appearance.

Application: Modified fibers have a wide range of applications, both in natural fibers and chemical fibers. Chemical methods are used to improve the incomplete performance of fibers.

- Multivariate Differentiated Fiber

Function: The multiple combinations of differentiated fibers can enable fibers to obtain new and different appearance and internal performance characteristics in multiple aspects.

Application: Various differentiated fibers can be combined in various ways.

- Natural differentiated fibers

Function: The differentiation of natural fibers aims to overcome their own weaknesses, improve their performance and functions, make natural fibers more suitable for the requirements of modern clothing, and become more competitive in competition with chemical fibers.

Application: Wool fibers can be modified in various ways, such as acetylated wool, which can improve their ability to resist mold and moths; Formaldehyde treated wool can increase alkali resistance, cooking resistance, and insect resistance; Chlorinated wool can reduce shrinkage; Ultrafine curled wool is also made through modified processing technology, and the fabric woven from it is lightweight, soft, smooth, and delicate.

High functional fibers

High functional fibers, also known as high-performance fibers, high-tech fibers, engineering fibers, etc. High functional fibers are different from general performance fibers in that some of their performance indicators are significantly higher than conventional fibers. The acquisition and application of these functions involve high-level science and technology, as well as edge science, hence they are also known as high-tech fibers. These fibers are mainly used in special fields such as industry and military. So it is often referred to as industrial fiber or engineering fiber.

- High-performance mechanical fiber

Definition: High performance mechanical fibers generally refer to fibers with high strength, high modulus, high specific strength, high specific modulus, good wear resistance, and fatigue resistance, but generally low tensile strength.

Usage: These fibers have many excellent properties and have excellent applications in various fields such as aerospace, ocean, construction, metallurgy, chemical engineering, automobiles, precision instruments, sports, and medical treatment.

- High-temperature resistant fiber

Definition: High functional high-temperature resistant fibers need to meet the following conditions: maintain certain mechanical properties at high temperatures; Long term use at high temperatures reduces cracking; Possess the processing performance of fiber materials. It is generally believed that high-temperature resistant fibers remain unchanged within at least 150 ℃, do not soften at 300-350 ℃, have flame retardancy, fire resistance, and heat resistance, and do not melt in air.

Usage: High temperature resistant fibers are currently widely used in industries, transportation, aerospace, energy, and other fields, such as heat resistance, insulation, filling materials for insulation, furnace cores, fire-resistant fabrics, fire-resistant clothing, fire-resistant curtains, protective equipment, high-temperature filtering materials, firefighter uniforms, aerospace insulation tools, etc.

- Electrical functional fiber

Definition: Electrical functional fibers are fiber materials with conductive properties, mainly used to overcome the problem of static electricity. Ordinary textile fibers are poor conductors, while synthetic fibers have hydrophobicity, making them more prone to generating static electricity, causing various obstacles and making production difficult; It also causes trouble when using the fabric, which can easily adsorb dust, stain, fuzz, explode, and so on. In other industrial production, the problem is even greater, such as easily causing fires and explosions in petrochemical industry; In the manufacturing of pharmaceuticals, electronics, and precision instruments, dust adsorption or discharge can easily cause harm and component damage. For this reason, people are committed to researching anti-static methods. Conductive fibers are an important way to remove static electricity.

Usage: Electrical functional fibers can not only prevent static electricity, but also serve as heating agents. The heating fibers developed in recent years can be used for indoor products such as cold resistant clothing, daily necessities, healthcare, bedding and blankets, as well as for insulation materials, building materials, agricultural seedbeds, etc., with significant effects.

- Separating functional fibers

Definition: Fibers with super strong separation function.

Usage: Separation functional fibers have a wide range of applications, such as water treatment, including seawater freshening, hard water softening, industrial water purification, manufacturing of ultrapure water and wastewater treatment, as well as various waste recycling, filtration and separation in the food industry, pharmaceutical industry, and chemical industry.

- Other high-performance fibers

Other high-performance fibers, such as optical performance fibers, magnetic properties fibers, high chemical stability fibers, high elasticity fibers, soluble fibers, adsorption fibers, etc., can be said to have their own unique functions, and their applications are also quite wonderful. It is a secret weapon for new product development and also worth our close attention.

The changes and development of fibers are truly unexpected. The development of high-performance fibers may seem far from ordinary clothing, but their superior performance and astonishing development speed are quietly infiltrating into ordinary clothing fabrics.

Comparison of Different Fibers

When designing clothing, it is often necessary to choose appropriate fiber materials based on the purpose, requirements and required performance of the clothing. Therefore, it is necessary to understand the advantages and disadvantages of different textile fibers properties, as well as the comparison with other fibers, in order to learn from each other’s strengths avoid weaknesses, and select them reasonably and effectively. The following is a ranking of the main characteristics of each fiber, which is only a qualitative relationship and is more intuitive and easy to grasp. If you want to quantitatively understand specific data, you can further consult relevant materials.

-

Density

The density of textile fibers refers to the mass of fibers per unit volume. It is related to the coverage and weight of clothing. The order is: polypropylene<spandex<nylon<acrylic<vinylon<nitrile chloroprene<acetate fiber<wool<silk<polyester<copper ammonia fiber<hemp<viscose fiber<cotton<polyvinyl chloride fiber<glass fiber.

-

Strength

The strength of a fiber refers to the force required for the fiber to break due to stretching. Due to the different thicknesses of fibers, it is difficult to compare them. Therefore, the maximum tensile force that a fiber can withstand per unit of fiber fineness is compared using relative strength. The order is: hemp>nylon>polypropylene>polyester>vinylon>cotton>silk>copper ammonia fiber>viscose fiber>acrylic>chlorine fiber>acetate fiber>wool>vinylidene chloride fiber>spandex.

-

Elongation

The elongation of a fiber refers to the elongation value generated when the fiber is stretched to break. It reflects the deformation performance of fibers. The order is spandex>chlor>nylon>polypropylene>acrylic>polyester>wool>vinylidene chloride>silk>viscose>vinylon>copper spandex>cotton>hemp>glass fiber.

-

Elastic modulus

Elastic modulus is an indicator used to represent the initial state of deformation of textile fibers under tensile force, also known as initial modulus. A low modulus of elasticity indicates that fibers are prone to deformation, and a small amount of force can cause significant deformation of the fibers. A high modulus of elasticity indicates that the fibers need to undergo a significant force before they begin to deform. Reflects the stiffness or softness of fibers. The order is: hemp>glass vinylon>strong fiber>silk>cotton>viscose fiber>chloroprene>copper ammonia fiber>polyester wheel>acrylic>acetate vinylon>vinylon>polypropylene>wool>nylon>polyvinyl chloride fiber.

-

Wear resistance

Wear resistance refers to the ability of fibers to withstand repeated external forces. Sorted as follows: nylon>acrylic>vinylon>polyester>polyvinyl chloride fiber>acrylic>spandex>wool>silk>cotton>hemp>strong fiber>copper spandex>acetate fiber>glass fiber

-

Thermal performance

Thermal performance

Thermal performance refers to the performance of textile fibers that undergo changes in their physical and mechanical state as the temperature increases and molecular motion intensifies during the heating process. Most synthetic fibers undergo several different physical and mechanical states under the action of heat: glass transition, softening, melting, etc; However, the melting point of natural fiber and natural protein fiber is higher than the decomposition point, so these fibers will decompose or carbonize directly without melting at high temperatures. According to different thermal properties, the appropriate temperature can be controlled for clothing shaping or leveling treatment.

(1) Softening point: Glass fiber>Polyester>Nylon 66>Vinylon>Acrylic fiber>Acetate fiber>Nylon 6>Spandex>Polypropylene fiber>Polyvinylidene chloride fiber>Chlorine fiber.

(2) Melting point: Glass fiber>Acrylic fiber>Acetate fiber>Polyester fiber>Nylon 66>Vinylon>Nylon 6>Polypropylene fiber>Chlorine fiber>Polyvinylidene chloride fiber

(3) Decomposition temperature: Viscose fiber>Copper ammonia fiber>Cotton>Silk>Hemp>Wool.

(4) Dry heat resistance: glass fiber reinforced polyester>aromatic polyamide fiber>polyester>acrylic>vinylon>nylon>cotton>polypropylene>wool>Chlorine fiber.

(5) Moisture and heat resistance: glass fiber>aromatic polyamide fiber>acrylic fiber>polypropylene fiber>cotton>polyester, vinylon>wool>cChlorine fiber.

-

Sunlight resistance

Sunlight resistance refers to the indicator of the strength loss of fibers under sunlight exposure. This is important for clothing that is often worn outdoors. The order is: glass fiber>acrylic fiber>hemp>cotton>wool>acetate fiber>polyester>polyvinylidene chloride fiber>high-strength fiber>glossy viscose fiber>vinylon>matte viscose fiber>copper ammonia fiber>spandex>nylon>silk>polypropylene fiber

-

Specific resistance

The specific resistance of the fiber surface is numerically equal to the resistance value when the material surface width and length are both 1cm. High resistance is manifested by the tendency of fibers to accumulate static electricity, adsorb dust, adhere to the skin, and hinder activity. The order is chloroprene>polypropylene>polyester>nylon>spandex>wool>acrylic>vinylon>silk>cotton, linen, and viscose fibers.

-

Hygroscopicity

Hygroscopicity refers to the ability of fiber materials to absorb or release gaseous water in the air. The moisture absorption of fibers is directly related to the comfort performance of clothing, as well as electrical and thermal properties. Under standard conditions, the order of fiber hygroscopicity is wool>jute>viscose fiber>high-strength fiber>ramie>silk>cotton>vinylon>nylon 66>nylon 6>acrylic>polyester>polypropylene.

-

Acid resistance

Acid resistance refers to the resistance of fiber raw materials to acidic chemicals, which refers to the chemical properties of fibers. When choosing dyes, finishing agents, detergents, etc., it is necessary to consider the chemical properties of the fibers and make targeted choices, otherwise, it may cause damage to the fibers. The order is: polypropylene>acrylic>modified acrylic>vinylidene chloride>polyester>glass fiber>wool>nylon>silk>cotton>polyester fiber>viscose fiber.

-

Alkali resistance

Alkali resistance refers to the resistance of fiber raw materials to alkaline chemicals. When choosing dyes, finishing agents, detergents, etc., it is necessary to consider the chemical properties of the fibers, otherwise, it may cause damage to the fibers. In addition, different chemical finishes can be carried out by utilizing the chemical properties of fibers. The order is nylon>polypropylene>polyvinylidene chloride fiber>modified acrylic>glass fiber>cotton>viscose fiber>polyester>acrylic>acetate fiber>wool>silk.

-

Easily dyed fiber

Easy-to-dye fibers refer to fibers that can be dyed using ordinary dyeing methods, and there are many types of dyes that can be used. They are cotton, viscose fibers, wool, silk, and nylon.

-

Difficult to dye fiber

Difficult-to-dye fibers refer to fibers that require special dyeing methods to be dyed, and the dyes available are relatively limited. They are polypropylene, chloroprene, polyvinylidene chloride fiber, and polyester.